Structural steel fabrication is the process of taking raw steel and cutting, bending, and welding it into a useful structure. Structural steel is used in a variety of applications, from skyscrapers to residential buildings, bridges, and even boats, and the fabrication process is an integral part of the construction process. You can also click on https://8starmetalengineering.com.au/services/structural-steel/ if you want to hire experts for installing structural steel fabrication.

Image Source: Google

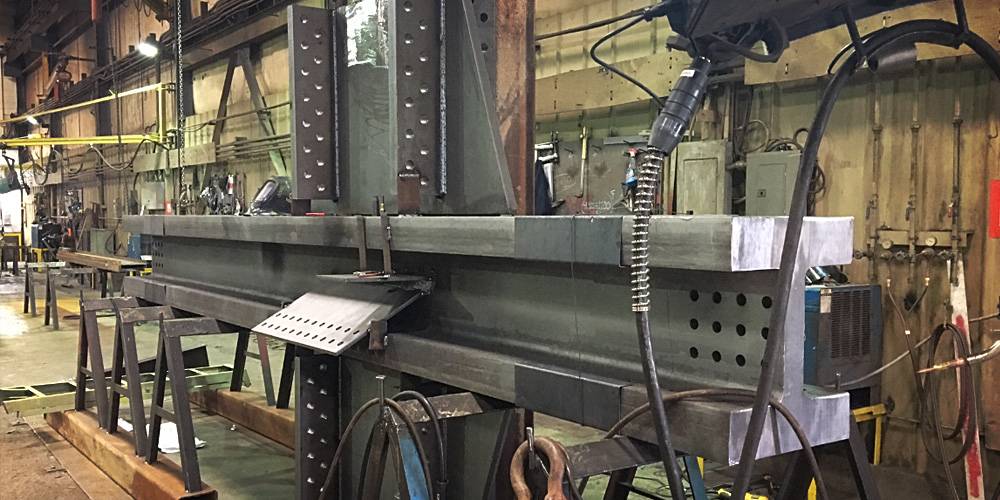

The process begins with the steel being cut into the desired shapes and sizes, either through computer numerical control (CNC) machines or by hand. Once the pieces are cut, they are bent into shape using a press brake, an automated tool that can bend metal into complex shapes. The pieces are then welded together using gas or arc welding techniques.

After the pieces are assembled, they can then be treated with a surface finish to protect against corrosion and UV damage. This can range from a simple paint job to a full galvanized coating.

The next step is to inspect the steel to ensure that it is up to code and that there are no defects. Once the inspection is complete, the structure is ready to be installed. This process typically involves the use of cranes and other heavy equipment to lower the steel into place.

Finally, the structure is tested to make sure that it is able to withstand the forces it will be exposed to and that it meets all safety standards. Once the testing is complete, the structure is ready to be used.

Structural steel fabrication is a complex process that requires a lot of skill and attention to detail. However, the end result is a structure that is strong, durable, and safe.